By Hongbai Lao, Iridian Spectral Technologies

Drug developers depend on accurate identification and molecular analysis of the components within pharmaceuticals to optimize product quality across solid and liquid formulations. Since a unique Raman spectral fingerprint exists for every molecule, Raman spectroscopy is increasingly the preferred technique to examine the structure and distribution of components within drug formulations. In addition to serving drug design, Raman spectroscopy informs process analytics, supports patent infringement cases, and enables precise counterfeit analysis.

The Raman technique is fast, quantitative, non-invasive/non-destructive, and is unaffected by water. Limited or no sample preparation is necessary, and numerous portable/flexible configurations can be achieved using various instrumentation and optical filters. In fact, choosing the right filter or combination of filters is essential to effectively identifying drug components and characterizing their homogeneity.

The Impact Of Optical Filters

As discussed in a previous article, Raman spectroscopy utilizes a high-intensity laser source to illuminate a sample and then analyzes the inelastically scattered Stokes and/or Anti-Stokes light emitted. The same spectral information can be obtained using a range of laser excitation wavelengths, but the emitted light is very close in wavelength to the excitation light. Therefore, steep filters are required to attenuate the laser signal from reaching the detector while transmitting the weak emitted light signal.

Drug characterization applications typically combine a single dichroic filter (long pass dichroic and short pass dichroic, DLP and DSP) and a single edge pass filter (long pass and short pass, LPF and SPF), but a second edge pass filter often is added to improve signal-to-noise ratio. Notch filters are sometimes used, as well.

The filter requirement is based on the drug components a user seeks to identify/characterize. The user must understand the Raman shift spectral range of the specific drug particles or contaminants they are trying to detect and then look for suitable filters operating within that range. Users generally have access to a library of spectral ranges associated with certain particles, but they need guidance in identifying suitable filters for that application.

Notably, the spectral information required varies for different types of filters. Factors that can impact filter performance include angle of incidence (AOI), laser beam size and laser wavelength variation, filter dimensions (un-mounted or mounted, plus mount size) and tolerance, polarization requirement, filter clear aperture, and environmental operating conditions. The cumulative effect of these parameters is not necessarily intuitive, and small changes can have a large impact on a filter’s overall spectral performance. For filters commonly applied to drug characterization, users should consider the following key factors:

- Edge pass filter (LPF and SPF)

- AOI and range, Cone half angle

- passband transmittance wavelength range(s) and level(s)

- ripple spec (allowed transmittance variation) for the pass band range(s), if applicable

- reflection or blocking band range(s) and level(s)

- cut-off value and/or edge steepness

- Notch filter

- AOI and range, Cone half angle

- reflection or blocking band range(s) and level(s)

- passband transmittance wavelength range(s) and level(s)

- ripple spec (allowed transmittance variation) for the pass band range(s), if applicable

- Dichroic filter (DLP and DSP)

- AOI and range, Cone half angle

- passband transmittance wavelength range(s) and level(s)

- ripple spec (allowed transmittance variation) for the pass band range(s), if applicable

- reflection or blocking band range(s) and level(s)

Iridian Spectral’s Filter Expertise

Iridian Spectral offers a range of standard Raman filters and custom solutions, but the possibility always exists that a distinct filter combination will be required for a particular application. Accordingly, we can customize filter design to meet customer requirements as well as optimize existing designs to fit specific applications or spectral detection parameters set by the Raman instrument user.

Iridian’s custom Raman edge filter solutions boast exceptionally high transmittance levels and blocking over a wavelength range between 320 nm and 2m. Meticulously designed using in-house software and multiple process options refined over more than 20 years’ experience in numerous applications, our filters all are deposited using energetic sputtering (or evaporation between 10 and 15 μm), ensuring a durable, environmentally stable coating. Moreover, these filters are capable of operation across single or multiple bands, as well as multiple zones.

Thus, Iridian can help customers to optimize LPF performance and cost according to their Raman spectroscopy needs (Table 1). Our experts are also available to customers post-sale to support optimization of their Raman systems and to discuss how we can facilitate system improvements in the future.

| Specification | Lower Cut-off | Good Cut-off and Extended PB Range |

|---|---|---|

| Edge Cut-Off (“steepness”) | <50 cm-1 (as low as 25 cm-1) | <100 - 200 cm-1 |

| Laser Blocking Depth | >OD 6 | OD6 |

| Spectral Range | Laser Wavelength - 1200 nm | 300 - 2000 nm |

| Passband Wavelength Range | Up to 1200 nm | Up to 2000 nm |

| Blocking Wavelength Range | Laser wavelength + / - 2-3 nm | 300 nm – Laser wavelength |

Table 1 —Iridian Spectral Long Pass Edge Filter Capability Range

Drug developers new to the technique may wish to build a library of optical filters right away, or they might just want to build their collection as needed. Both approaches are viable, since Iridian usually can optimize a filter design to customer specifications within one to two weeks. Moreover, one filter often can be applied to the detection of multiple particles, i.e., those that share a spectral range, and high-quality filters can be used for multiple applications.

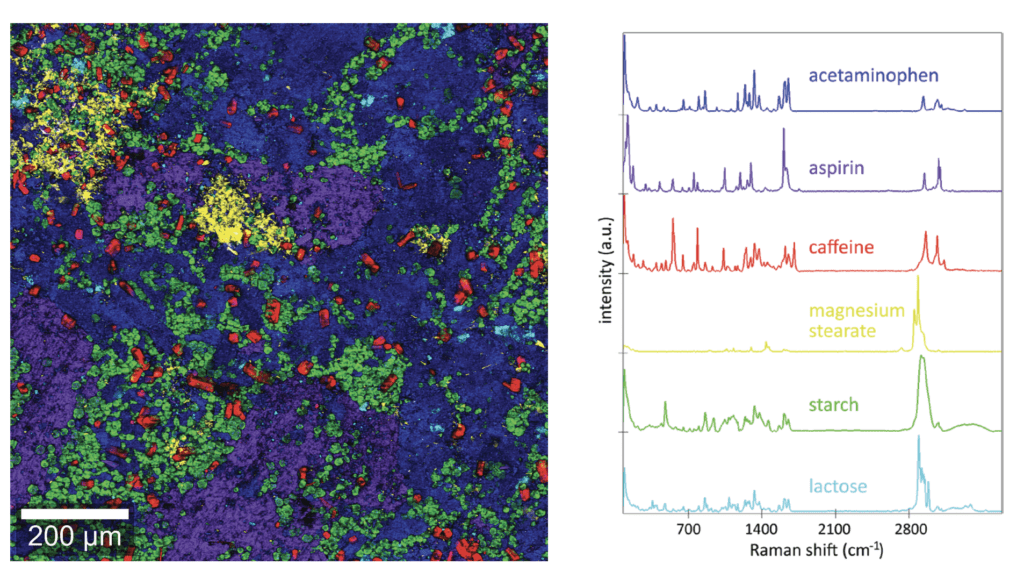

An example of the drug quantitative analysis by the Raman image technique is shown in Figure 1 illustrating the Raman analysis of a painkiller tablet with the characteristic Raman shift spectra (source of information and images: WITec GmbH, a Raman instrument company).

Figure 1 — (A): High-resolution, large-area Raman image of the tablet’s surface; (B) Raman spectra: acetaminophen (blue), aspirin (purple), caffeine (red), magnesium stearate (yellow), starch (green), lactose (cyan)

A Superior Technique

Precise use of filters gives Raman spectroscopy fantastic utility not only in drug identification and inspection but also the detection of explosives and unknown substances, materials inspection by U.S. Customs and port authorities, and food safety inspection. For example, The FDA’s Trace Examination Section (a unit of its Forensic Chemistry Center) examines the legitimacy of drug products using Raman spectroscopy “for counterfeit and unknown particle analysis.”1

Other techniques, including infrared (IR) spectroscopy and some chromatography methods, can be applied to the quantitative analysis of drug product, but they lack the advantages of Raman spectroscopy — most poignantly its non-invasive/non-destructive nature and its speed. Raman spectroscopy can accomplish full spectrum analysis in just a few minutes. Still, this utility is only unlocked through use of proper filtration with optical filters. To learn more about choosing the right optical filter(s) for your drug ID applications, contact the author and visit https://www.iridian.ca.

Resources

1. “Raman and IR Spectroscopy Identifies Counterfeit Drugs.” Horiba, Spectroscopy Matters blog. https://www.horiba.com/pol/scientific/resources/spectroscopy-matters/raman-and-ir-spectroscopy-identifies-counterfeit-drugs/