Frequently Asked Questions

What are optical thin film filters?

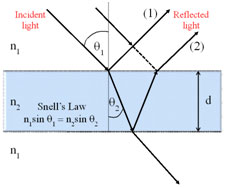

If you see a rainbow pattern on a soap bubble or on a film of oil you are seeing a simple optical thin film in action. Wavelength dependent constructive and destructive interference occurs when light interacts with material layers of thicknesses that are fractions of the incident light. When the thickness of the film corresponds to an integer (m) multiple of the wavelength of light constructive interference occurs according to:

2n2dcos(Θ2) = m λ

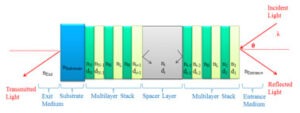

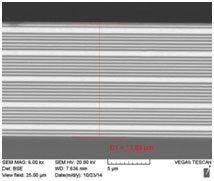

At Iridian we put this basic thin film physics to work by depositing onto substrates (typically glass) optical thin film filters consisting of alternating layers of high and low refractive index materials. Often these layer stacks consist of 10’s to 100’s of individual layers. The individual layer thicknesses are on the order of 10 nm to 1000 nm thick depending on the spectral range of the optical filter (the layers thickness are often ¼ of the wavelength region of interest). The result is selective transmission and reflection of specific wavelength bands dependent on the effective thickness of the film and the layer structure deposited.

How are optical thin film filters manufactured?

The deposition and substrate materials are selected on the basis of their optical and physical properties for the operating wavelength range of the filter as well as for the ability to be deposited in a controlled and efficient manner and with the requirement that the resultant thin film filter be robust and durable. Dielectric oxide materials are usually the material of choice for visible (350-750 nm) and near- and mid-IR (750-9000 nm) spectral range (for UV and long wave IR wavelength ranges, selenides, sulfides, fluorides and semiconductors are often employed). These coating materials can be deposited by different mechanisms but at Iridian we typically employ energetic sputtering processes (we use evaporation in the 10-15um wavelength range) to efficiently produce in a repeatable, high yielding manner, complex, precise and robust filter stacks.

Optical thin film filter software is employed by thin film engineers to design the thin film multilayer based on the chosen materials and required optical and physical specifications. In order to realize the desired optical performance, the optical constants of the deposited thin film materials need to be accurate and the layer thicknesses tightly controlled, typically to within 1 nm, for deposition runs that can last from a few hours to several days. Modern thin film deposition systems employ in-situ optical monitoring to ensure that the layers are accurately deposited; the control software can then automatically adjust subsequent layers based on the in-situ feedback to produce the desired final filter shape.

What functions do optical thin film filters perform?

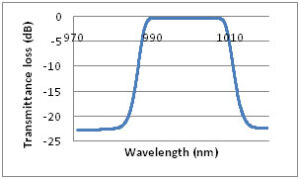

Optical thin film filters are designed to transmit, reflect or absorb specific wavelength ranges of light for one or more angles of incidence and for different polarizations of light. At Iridian most of the optical filters that we produce provide “wavelength selectivity” to the devices in which they are implemented; that is they transmit specific wavelength regions and reflect or block others providing “more signal, with less background” to the systems in which they are deployed.

Optical filters are used in diverse applications:

- communications

- telecommunication networks and data centers

- wavelength division multiplexing (WDM), fiber amplifier gain flattening (GFF)

- optical inter-satellite links (OISL) for satcom

- telecommunication networks and data centers

- analytical/spectroscopic instruments

- Fluorescence or Raman imaging and analysis

- molecular viral testing (qPCR), biomedical analysis, airport/haz-mat/process material scanning

- remote sensing/detection

- gas detection, Earth observation from satellites, LIDAR

- consumer entertainment

- projection displays, 3D cinema

- many other areas!

- Fluorescence or Raman imaging and analysis

What should I look for in selecting a supplier of optical thin film filters?

As always, a balance of price and performance are primary considerations when selecting a supplier. However partnering with an experienced and responsive supplier that is willing to suggest trade-offs and possesses the proven ability to produce many different types of filters helps ensure that the optimal solution will be produced that addresses both commercial and technical needs of your product.

It is also critical that your supplier follows and is certified to a quality management system (such as ISO9001:2015) and that they have a team in place to support the filter from initial concept through to volume production if needed. Finding a supplier with the integrity to “ask permission rather than forgiveness” in negotiating upfront deliverables such as performance and lead-time, and that is available to support questions throughout the build and product life-cycle is invaluable.

What are the advantages of Iridian’s optical thin film filters?

Thin film optical filters have a number of distinct advantages compared to other optical technologies for reflecting, transmitting or absorbing various spectral regions. For example, optical thin film filters:

- Can be fabricated in small or large sizes (from <1.0×1.0×0.15 mm to >150×300×20 mm)

- Are environmentally very stable (when using an energetic deposition process such as sputtering)

- Can have customized spectral performance

- Can be designed to have either a very small or a large wavelength shift with temperature

- Work over a broad wavelength operating range

- Can be prototyped quickly and affordably

- Can be manufactured repeatedly in high volumes

- Have a long history of use and are an established technology

What are the names of the various wavelength ranges?

- UV (250-380 nm) [UV = Ultra-Violet]

- VIS (380-750 nm) [VIS = Visible]

- NIR (750-1400 nm) [NIR = Near Infra-Red]

- SWIR (1.4-3.0 µm) [SWIR = Short Wavelength Infra-Red]

- MWIR (3.0-8.0 µm) [MWIR = Mid Wavelength Infra-Red]

-

LWIR (8.0-15 µm) [LWIR = Long Wavelength Infra-Red]

In addition, for Telecom applications, there is a set of bands defined that are commonly used:

| Band | Description | Wavelength range |

|---|---|---|

| O band | Original | 1260–1360 nm |

| E band | Extended | 1360–1460 nm |

| S band | Short | 1460–1530 nm |

| C band | Conventional | 1530–1565 nm |

| L band | Long | 1565–1625 nm |

| U band | Ultra-Long | 1625–1675 nm |

How should I specify custom requirements for an optical thin film filter when requesting a quote?

For a specific filter product types, additional specifications are usually required. For example,

- Gain Flattening Filters (GFF) –

Need to specify: Target transmittance curve along with desired Peak-to-Peak Error Function (PPEF) - Solid Etalons –

Need to specify: Free Spectral Range (FSR), Finesse (F) and FSR temperature variation. - Single Cavity Etalons –

Need to specify: -3 dB bandwidth (equivalent to the Full-Width, Half-Maximum (FWHM) is specified - Bandpass, Edge Pass Filters –

Need to specify: transmit and reflect band(s) and allowed insertion loss (IL), ripple and blocking levels

How do I generate a Request For Quotation (RFQ)?

What information is needed for a Purchase Order (PO)?

- Quotation number and date,

- Preferred courier and your account number with that courier,

- If you are a first time buyer and request a 30 days credit, please include credit ref

Can I order online?

Yes you can order online for any single band fluorescence filter or set, see our NEW web store for product listings! We will be adding additional products shortly and welcome your inquiries for any other items on our website. We can accept telephone orders using VISA cards or standard purchase order for any of our products.